For many leading manufacturers, Emulsichem provides a technical support package for supply and management of our cutting fluids. Effective coolant management provides reductions on your total cutting fluid spend.

Greater asset utilisation.

Reduced downtime

Improved production rates

Reduced rejection rates

Extended tool life

Reduced coolant usage

Reduced waste disposal costs

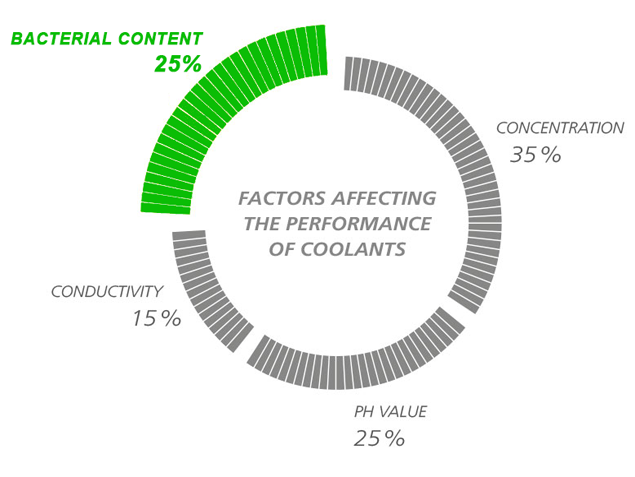

Emulsichem offers an initial in depth manufacturing site survey carried out by metalworking fluid technicians and fluid management consultants. The survey looks at all operations and processes impacted by the cutting fluid, resulting in a detailed plan of potential improvements using Emulsichem in house technology. The survey provides a plan of how costs can be saved across the full manufacturing process, rather than simply look at “cost per litre” savings. During the survey process, our engineers will look at:

Fluid technology on site

Emulsion strength

Tooling spend

Waste management

Maintenance costs

Downtime minimisation

Health and safety requirements

Training on coolant ‘best practices’ to employees.

Following each site visit we will provide customers with instructions of necessary actions as well as all support documents to ensure that you are able to get an immediate overview of fluid condition.